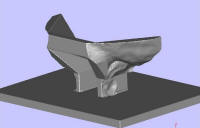

Rapid prototyping/manufacturing offers the unique ability to achieve complex and accurate geometries, including anatomical features, from a wide range of materials that includes plastics and even metal. While RP is often used for prototyping, it can also result in a sturdy and usable part for low-volume or custom applications at a reasonable price.

ATI’s experience with RP has been in converting medical image data from CT scans to usable models, but the potential application for the technology is even wider in scope. The potential for design low-volume and low-cost industrial fixtures and equipment or customized consumer applications in additional to medical devices and instruments sets ATI apart from other design and engineering firms.