|

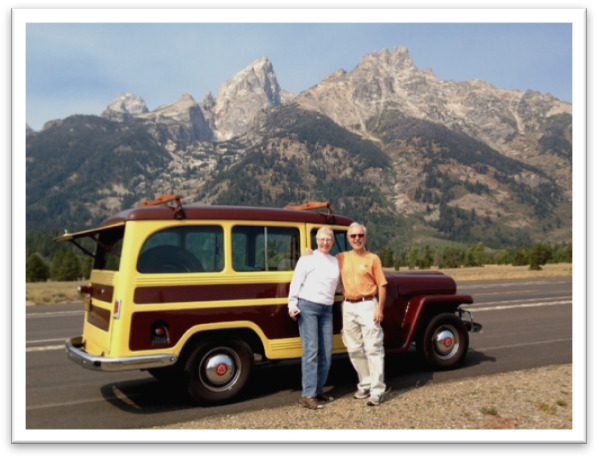

Follow Jean and Dan’s recent Treks around the United States in their 1950 Willis Overland Jeep Station Wagon

|

When it comes to engineering design companies, here is why Applied Technologies

stands out:

stands out:

We are product and process development experts – specializing in the medical,

transportation, tool hire and electronics industries.

transportation, tool hire and electronics industries.

Our multi-disciplined engineers and proven resources support our clients at each stage of

product development from concept creation and refinement, to detailed design, prototyping,

evaluation, support of tooling and manufacturing activities.

product development from concept creation and refinement, to detailed design, prototyping,

evaluation, support of tooling and manufacturing activities.

|

SUPPORTING YOU THROUGH

EACH STAGE OF DEVELOPMENT |

||

|

“We found that ATI’s experience in product design and materials, and their ability to conduct a detailed analysis of our product and production methods greatly assisted us in focusing on the key issues in upgrading our end-product’s performance. Thank you.” |

||